It is terrific how most of today’s automobiles are nearly maintenance free (except for oil changes and long-term stuff). Tech bindings such as Dynafit and G3 Onyx are an even better set-it-and-forget-it proposition. I know guys who’ve run the same set of Dynafits for half a decade without lubrication. But just as you’ll eventually have to change your transmission fluid or flush your radiator, sometimes tech bindings need love too.

Until today, the eternal question in all this is what grease do you use? In the factory, they use lubes that are specified for plastic parts (Dynafit is said to use Dow Corning Molykote EM-30L). it’s possible to get such lubricants (they’re sold as gear lube for model cars and computer printers, though they may not perform well in the cold).

Instead of something proprietary or as hard to get such as Molykote, I’ve found that plain old white lithium lube works fine. I tested in my freezer and it gets stiffer when colder, but doesn’t lock up. And after years of use I have not seen any plastic degradation (it comes in a plastic tube with a plastic cap.)

Better still, guess what arrived at WildSnow HQ the other day? Yep. G3 binding grease that’s said to be as good or better than Molykote, and most certainly is better than white lithium. (Note: G3 Binding Grease should soon be available at selected retailers and etailers, MSRP $31.90 for a large tub that’ll last a long time.)

Here is what a G3 product development engineer told me about their grease:

The grease we use and now sell is not that far off what you have suggested in the Molykote EM-30L. Key for us was low temperature performance, high load carrying capacity, compatibility with acetal (editor’s note: Delrin plastic), and friction reduction for sliding plastic parts. Although Molykote grease is very similar to our requirements. Where I *think* the grease we use differs is:

– definitely a little thicker and stickier

– provides better water washout resistance

– lower coefficient of friction (in theory)This is based on review of the spec sheets, which of course never seem to offer exactly comparable test data or specs, so I have to read between the lines a little. Given the choice, I think that grease we are using is a little more suited to the job of lubricating a binding. That said, when it comes to real world performance, both greases should do a good job without ruining bindings. Ultimately the goal for the G3 binding grease is to be able to provide the same high quality OEM grease we use building the binding to dealers and shops so that they can service the bindings and maintain a high level of performance.

White lithium grease from the hardware store, works fine but dedicated binding grease is better.

In the case of Dynafit and other tech bindings with the same type of heel construction, the aluminum “heel spindle” post that the heel unit rides on can be susceptible to lack of lubrication after high mileage or abuse such as repeated water immersion or road salt exposure. (In the latter case, road salt can work havoc on any ski bindings — if possible NEVER expose your bindings to it, and if you do, flush binding with tap water as soon as possible, and dry in a warm/dry location.)

First step in lubricating Dynafit rear spindle is removing rear spring barrel. Only tackle this if your binding doesn't rotate smoothly and doesn't snap back to center after being rotated by hand. Re-inserting the rear spring barrel is tricky, VERY easy to cross thread!

Onyx bindings have a different configuration in the heel unit. At first glance Onyx appears similar to Dynafit, in that during lateral release a plastic housing rotates on the heel spindle. But instead of the lateral release mechanism being internal in the housing over the spindle as it is with Dynafit, the Onyx housing instead has a couple of external lobes that press and rotate against a spring loaded piston.

In my real world experiments, I wasn’t bold enough to remove the Onyx heel unit from the spindle, as doing so requires removing a large machine screw that felt permanently installed. That’s fine, as it would be rare to need to clean and lubricate this tightly enclosed space. On the other hand, the Onyx external lobes and piston could indeed attract dirt, or loose their lubrication after exposure to excessive moisture such as road salt spray. Photos below tell more of the Onyx story.

Onyx rear spindle, underside. Arrow indicates large machine screw you’d have to remove to extract spindle from housing. It would be rarely necessary to do this, as the actual lateral release mechanicals are located OUTSIDE of the spindle housing.

Looking at Onyx heel unit underside. Arrow indicates EXTERNAL lateral release lobes where lubrication could possibly be required.

The most important two points in this:

1. Do not bother taking your bindings apart and lubricating if the heel rotates smoothly and freely. If they need lube you can feel it being kind of sticky and sluggish to return to center.

2. Known that re-inserting the Dynafit rear spring barrel is incredibly tricky — even look at it sideways and you’ll cross thread it. Repair is expensive.

3. The mechanism hidden under the top plate of both the Dynafit and Onyx heel units is complex and rarely needs lubrication. If you do need to lube this part of the binding, see Dynafit disassembly and assembly instructions here. Onyx tear down is similar.

Onyx heel with top cover removed. With both Dynafit and Onyx these internals are well lubricated at the factory, and somewhat protected. They rarely (if ever) need cleaning or lubrication. Nonetheless, bindings that receive heavy use over several years may eventually need clean and lube of these parts. Yep, another blog post about that coming up in the future.

In the case of Dynafit, if you do need spindle lube job, use a wide blade screwdriver to remove the rear spring barrel. Pull out the springs you’ll see underneath, then use a pick or the corner of a screw driver to pull the internal thimble bushing rearward so you can lift the housing off the spindle. Complete directions for this process can be found here.

In the case of Onyx, simply remove the heel unit from its carrier plate (the “swap” plate attached to the ski). Working from the underside of the heel unit, rotate the lateral release mechanism so you can see the moving lobes. Inspect for dirt and lubrication. If necessary clean with a small stiff brush then lubricate.

In the case of any tech binding, NEVER clean any plastic parts with solvent, especially when the binding is still assembled. Doing so can damage the plastic, and if the binding is assembled you could end up with solvent trapped who knows where, eating away at plastic parts.

After you get the Dynafit heel unit off, clean the spindle and surrounding parts. Don't worry about cleaning inside the housing, unless it's got grit or salt in it. In that case you can clean with a bit of WD40 on the tip of a rag.

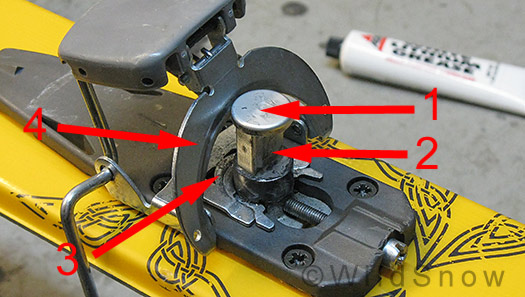

Spots for lube: 1 & 2: Smear some grease on top of the spindle and around the sides, especially on the back where the thimble bushing rides. 3: A bit of grease on the metal where the bottom of the heel unit may rub a bit. 4: Rub some alpine wax on the brake retraction plate.

Last thing, remember, be super careful not to cross thread the spring barrel. I’ve found that inserting the spring barrel first with my fingers and making sure it turns and threads easily helps with cross threading prevention, as does visually inspecting the barrel after you get it started in the threads, to make sure it’s not going in crooked. Also, be sure the thimble bushing and spring are all the way in before you insert the barrel, if the spring and bushing don’t seem to want to go in all the way, try pressing down on the top of the heel unit as you work the bushing/spring combo in.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.