Rando ski boot cuff pivot wear is the elephant in the room, the gorilla in the attic. Its the animal that takes a $1,000 shoe and makes it resemble a pet chew: A few bites by the big fido (you, we trust), and they’re a mess. Loose, wiggly, simply not what you paid for.

Dynafit’s take on this is twofold. First, they’re saying that any product with a hinge has a certain life span before it requires upkeep or replacement. In the case of backcountry skiing boots, that means at least re-pressing the cuff rivets every so often, or even replacing them. But how much do you want to do that, and if the holes in the boot shell get egged out, how does pressing the rivet help with that? It actually doesn’t, it is only a bandaid.

Better, the cuff rivet/pivot system on modern backcountry skiing boots should be designed as a bushing that at the least can take a lot of cycles, and at best is totally user renewable.

The former case is indeed being addressed by Dynafit, though I’d like to see them go farther with making the whole pivot system a replacable threaded bushing that could be swapped out in minutes. Whatever the future holds, next season’s Dynafit touring boots do address the pivot wear issue in various ways.

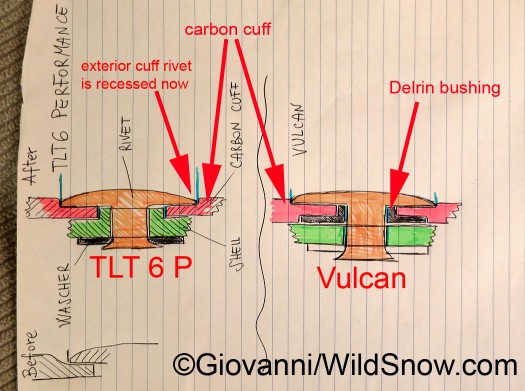

First improvement, as depicted in Dynafit boot ace Giovanni’s sketch above, is the external head of the boot rivet is recessed into the carbon boot cuff (as with what we recall is most ski boots). This gives a lot more wear surface due to the recess forming a lip around the edges of the fitting. Unfortunately, due to the cost of changing molds for the TLT6 (which uses the TLT 5 molds), that’s the only improvement you’ll see in the TLT boots in terms of cuff rivets. The recessed rivet head will help slow down the wear cycle, but more, it’ll make aftermarket mods easier due to it forming another area where a bushing system could ride or be anchored.

Better, as depicted by Giovanni, Vulcan not only has the recessed rivet head, but also features a built-in Delrin plastic bushing. This should help make the Vulcan pivot last much longer before upkeep is required.

Good to see Dynafit addressing the problem of cuff pivot wear. On the other hand, pretty obvious that all this stuff only goes part way. Again, what’s needed is a complete bushing system that’s easily renewed at home by the boot owner, or else built so it outlasts the rest of the boot. Either approach would be fine by us.

La Sportiva user serviceable cuff pivot bushing in $3000 Stratos Cube model boot. Me want. You want. Or, it's not a want, it's a need. Thing is, if one company is doing this, watch for it everywhere eventually. The rivet pivot, that is.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.