You know those pedestrian switches at stoplights? The ones that supposedly let the light computer know you’re waiting to cross and will bias the lights for you if you give it a slap? My family has always laughed at my theory that some of these do nothing, and are just there to appease the impatient who would otherwise walk against the light. Yeah, I’m crazy. But hey, are you sure every one of those is actually wired to the system and does something? SURE?

Likewise, I’m a skeptic when binding companies come up with “stiffeners” or “vibration dampers” working off a plate under the foot. First, some such systems can be shown to do virtually nothing except look good in the ski shop (no names will be mentioned), while others that show an effect on the test bench many still have little or no effect on the actual performance of your skis and bindings. Why? As one engineer I spoke with put it, “for that plate to do much if anything, it would have to have a significant amount of strength or damping in relation to the flex properties of the ski, otherwise it’s just too small a percentage to have any real effect on performance.”

Perhaps most importantly, on the lightweight Dynafit Radical FT ski touring binding this added mechanical system is piling on a significant 48 grams (1.7 ounces) per binding. Is it worth it?

We’ll report, but ultimately you’ll have to decide.

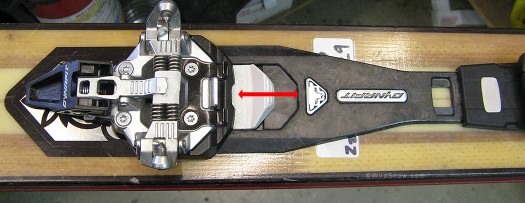

Dynafit Radical FT 12 'vibration damper switch' moves on and off as indicated by arrow. The question, does it really do anything?

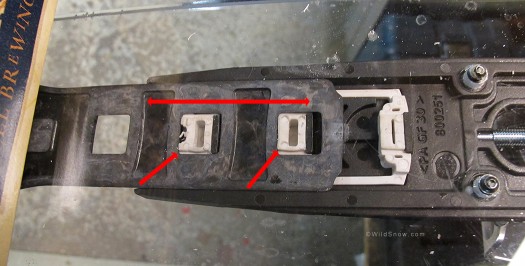

Underneath the Radical FT 12 connector plate, the white bumpers block movement of the semi-rigid black connector plate, as indicated by the horizontal red arrow. While this system undoubtedly has some effect as indicated by our extensive observation and bench testing, it is not beefy enough to be what we'd term a 'stiffener,' but rather is a somewhat minimal vibration damper.

Specifically, what about Dynafit’s Radical FT 12 “special plate that can be used for changing the stiffness of the system,” as this component is termed in the consumer info enclosed with the binding? First, know that most ski bindings have provision for the ski flexing under the foot (to avoid the dreaded “stiff spot”), but such provision usually has some form of inherent of vibration dampening either due to friction, or a spring and friction system. Tech bindings allow for flex, but have virtually no vibration damping. In other words, when the ski flexes, it moves the tech binding rear pins in and out of the boot heel fitting with no damping action or friction. That’s good when you want your ski to bend freely and indeed has been a well liked feature for years, but when you want some attenuation for things like ski chatter, you’re getting none.

When your ski flexes, the tech binding heel gap closes. In your average skiing with an average weight skier the heel gap remains open, allowing the ski to flex as shown to left above. But in aggressive skiing, perhaps with a larger skier or flexible ski, the heel gap can close to the point where the boot impacts the binding heel unit, as indicated in the right hand part of the double photo above. Oddly enough, Dynafit added a 'bump' on the heel unit that exacerbates this effect. Main point here is that the FT 12 damper system is likely intended to minimize this effect, though in our testing and evaluation we found any measurable or observable effect to be minimal.

What’s more, if the ski flexes hard, it can drive your boot heel against the tech binding heel fitting housing (see photo above) — possibly causing unintended release or even binding damage. The harder a ski is skied and the larger the skier, the more likely this is (and also the reason the tech binding ‘heel gap’ is such an important setting, not to mention the length of the pins). Hence, I’d agree with Dynafit that developing some form of damping or stiffening under the boot, between the binding toe and heel, is a good idea for aggressive skiing (so long as you can switch the system on and off, and it doesn’t add too much mass.)

Well, our dose of Dynafit coolaid had worn off some time ago (despite the constant accusations of bias we receive), so instead of assuming the FT-12 vibration damper worked, we did some bench tests to actually show what it does. First, terminology: Calling this a stiffness changer rather than a damper is I suppose fair, but a bit misleading as the system works not by rigidly connecting the toe and heel units, but rather by providing cushioning from small flexible dampers on the underside of the heel unit that slightly engage when the ski is bent into a turn. While this does make the binding and ski in one sense “stiffer” under the foot, a more accurate take is that it cushions the ski flex in that area, and is thus a vibration damper. More, during our testing we found that unless we added an unusual amount of flex to our simulated plexiglass ski, the system most definitely added nothing more than a very small amount of cushioning. So we’ll definitely call it a vibration damper, not a stiffener.

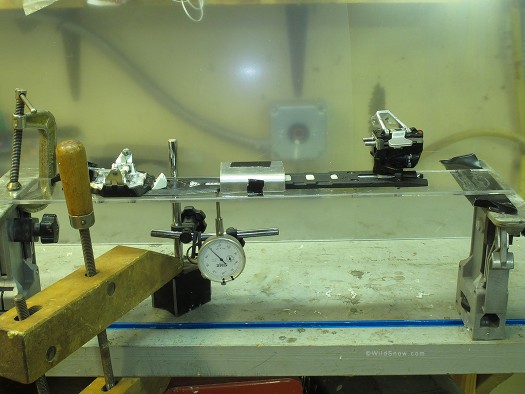

We designed this test to see if the 'vibration damper' actually had any measurable effect. We mounted the binding on a fairly flexible plexiglass demo board, which is suspended between two points with one end anchored and the other free to move on a lubricated surface. Underneath we set up a dial indicator reading in thousandths of an inch, then weighted the rig with 4.5 lbs (four Bud tallboys), this deflected the demo board 3/8 of an inch, which is roughly three times greater deflection than is possible with a boot blocking movement of the toe and heel unit. Thus, we exaggerated our simulated ski flex by a factor of three, because if we flexed our test rig to the max allowed with a boot installed (1/8 inch), we could not consistently measure the tiny result. The dial indicator was zeroed with no weight on the test rig. We made a bridge over the connector plate to prevent friction from the weight. We did nine measurement cycles, each time with the vibration damper switch on and off. As we did the test, the results were consistent enough to be meaningful, though slop in the system made it important to average the results. The average difference in deflection was 12 thousandths of an inch, again in a ski/plate flex range of 3/8 inch (.375 of an inch), so our deflection difference with damper on was 12 out of 375, or 3.2 percent (apologies for my math, the 12 thousandths is definitely correct, other numbers subject to checking this morning now that the extra tallboys have worn off). Again, we exaggerated the amount of flex to achieve this result, just to show that the system does function to one degree or another (considering we exaggerated the simulated ski flex by about a factor of three, and observable effect at less flex is quite minimal, it's probably safe to say that in real life the system has an effect of about 1% between being on and off).

Test rig weighted with four tallboys, for deflection of 3/8 (.375) inch. That's roughly three times more deflection than the binding can do with a boot installed, due to the heel gap closing up and the boot blocking for-aft movement of the binding toe and heel units.

Over-camber demonstration The ski (in this case demo board) curves so much the binding pins pull out of the boot heel. As far as we could tell, the Radical FT 12 stiffener/damper has no effect on this, as the movement it creates in the mechanics is simply too minimal.

Conclusion: As you can see from our images and testing, the mechanics of this system actually do have a mechanical effect that could be beneficial when the ski is curved (bent) as if in a turn. More, we also experimented with “over-cambering” the simulated ski, in the direction that sometimes pulls the pins out of the boot fitting in unusual situations or while super aggressive skiing. In over-cambering, the damper/sitffener has absolutely zero effect as far as we could tell.

How much of this damping or stiffening effect you’ll experience in real life is an open question. Indeed, as at least one skier has related to me, you can ski the binding with the system on or off and feel the difference. If so, terrific. If, on the other hand, you see no need for this extra plastic the binding can be easily mounted without, at a savings of 48 grams (1.7 ounces) per binding. Let us know your take!

(Note to home mounters: When doing a paper template mount, simply adjust distance between Radical FT 12 toe and heel unit so the damper system can be set to the “off” position and the connector plate mates with the obvious slots in the underside of the heel unit. Which slots you’ll usually mate the plate with is indicted by BSL numbers on top of the heel unit. If you choose to forgo mounting with the plate system, bed the toe unit in a nice puddle of epoxy just for good measure.)

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.