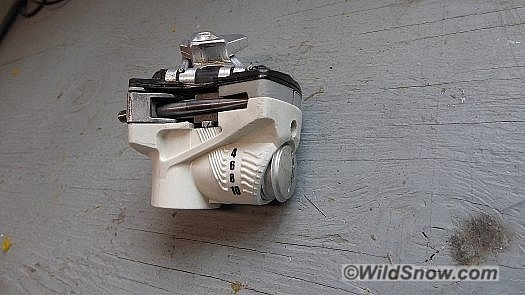

Getting tapped, you’ll need to insert tap far enough so the full diameter threads of the tap engage the stripped plastic threads. You can feel this happening. Don’t go too far in. Click images to enlarge.

I have stripped the Dynafit rear binding unit spring barrel cover (cap) threads more times than I’ll admit. Sometimes we’ve effected our ski touring binding repair by carefully inserting the barrel cover and getting it to eventually engage the housing’s plastic threads with correct alignment. Other times the bindings were replaced. In any case, with several decades of this involving myself and others here at the WildSnow shop, I’ve got quite a box of ruined heels. It is time.

One of our esteemed commenters asked about thread tapping the stripped heels to give them new life. I’m not sure why I didn’t do this sooner, but any time to begin something important is better than not beginning. The process is not rocket science but requires hand skills, and best, a bench vise to hold the tap. The challenge is getting the plastic heel unit to begin threading perfectly straight and not following any threads you’ve bunged up. I found that going slow and eyeballing alignment from different angles was the key. So, for around $17 perhaps you can repair a binding worth several hundred.

Required tooling: 20mm X 1.5 Metric HSS Right Hand Machine Tap.

Technical note: Some Dynafit spring barrel caps have a slot-cut in the threads that’s probably intended to help the cap thread easier during first install, or perhaps intended to provide a bit of “thread locking” effect. Problem, this small slot makes the cap act somewhat like a tap, thus making it even easier to cross thread. If your barrel cap has the slot in the thread, be extra careful installing after you think you’ve tapped and renewed the plastic housing threads.

Safety note: As always, this mod is at your own risk, and inspect any ski binding before every use. In the case of classic tech bindings, pay attention to the rear spring barrel, that it isn’t gradually backing out or loosening, and remains on the release value setting you intend. We suspect this could be a problem with some Dynafit as well as other brand tech bindings, especially when adjusted to lower settings. Clearing (chasing) the threads with a tap could exacerbate this occurrence as doing so causes to spring barrel cap to thread quite easily. It could be that a thread locking compound should be used. Over many years, we’ve not found that to be the case, but we’ve not run many bindings at ultra-low tension settings, and when we have run at low settings (as with children) we’ve not had any trouble with the spring barrel cap.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.