FAT torque wrench is marketing for firearm work, whatever your feelings about guns it’s actually a decent tool with a variety of applications.

I’ve never needed a torque screwdriver. Until now. My feel for tightening fasteners is pretty good. Decades as a pro carpenter and then more decades as a heavy do-it-your-selfer gave me muscle memory I take for granted, but is indeed something you’re not born with.

Nonetheless I mess up sometimes and enjoy that incredible sinking feeling as a fastener turns — and keeps on turning — this especially when I’m repairing pacemakers and Rolex watches. Kidding. Just. Tightening the tiny screws on classic tech bindings is a delicate operation, and mounting bindings on skis can result in damage from over tightening. A torque screwdriver helps.

My experiments with the recent G3 debacle took me to the land of nuanced torque, so I found something affordable on Amazon.

At a price of $45 I was skeptical that the “FAT Wrench” would fit the bill as most torque screwdrivers sell for significantly more, but the FAT is working quite well. This is a “clicker,” meaning you tighten the screw until the wrench “clicks” and releases, thus never applying more than your set amount of tightness. (Clarification due to comments: A clicker torque wrench clicks and releases, but most keep tightening the fastener if you continue to wrench. The FAT continues to click as you rotate and never applies additional torque above the setting.)

Tension is adjusted by pulling the handle top up and rotating, intuitive. Scale goes from 10 inch-pounds to 60, this can be changed to the more worldwide common Nm (newton meters) torque numbers using basic math (inch pounds x 0.1130 = Nm) or converters available online.

Using FAT wrench to tighten ION binding screws. Thickness of the 1/4 inch hex bit holder causes excessive angle that could cause you to damage screw heads, a longer torx 10 bit solves the problem so I ordered up a few of those.

FAT came with numerous elongated driver bits, but sadly not the torx 10 that some tech bindings require. So I got this 2 incher at the local hardware stealership and ordered a set on Amazon as well.

Even the elongated 1/4 insert bits are slightly too thick for straight-in angle on some screws. Shown here, the stainless steel screws of G3 bindings are especially prone to damage, so you want to be going in straight. The insert bit is easily modified for this, next photo.

I put the bit into an electric drill and did a nice grind on it while rotating. Near perfect angle to the screw head.

Last, but important:

Shown here, I checked calibration using my force gauge to rotate the torque wrench with a measured lever arm distance. Google ‘how to calibrate torque wrench’ for details. The FAT appeared to be reasonable quality and work quite well. If the torque you set ‘feels’ correct it is usable without a calibration check. I set it slightly below the 10 inch pounds to obtain the 8 inch pounds G3 specifies for the small screws on ION binding.

Torque wrenches can be inaccurate. If that’s the case, what good are the things? Being 10% off might not matter with your wheel nuts, but over tightened bolts that snap in half are not good. The FAT comes with a calibration card they do at the factory. I verified this with the testing illustrated above. You can buy a torque wrench calibrator — they’re used quite a bit in aviation. Expensive. Again, my take is you can use this tool without a calibration check if you combine the settings with a “feel” evaluation of the tightness you’re getting.

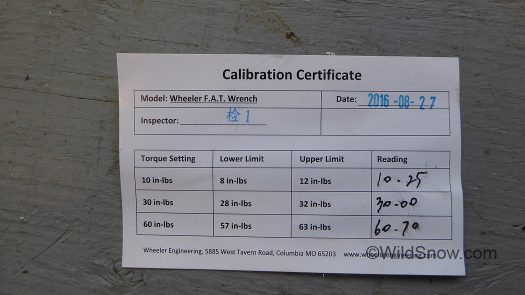

FAT comes with a surprisingly individualized calibration certificate. My testing with force gauge verified what the tester wrote on the certificate, as well as verifying I could get 8 inch-pounds by dialing a bit below the 10 on the tool’s setting scale.

I checked the FAT calibration by cranking it with my force gauge (photo above). Nice to see the measurements I got were quite close to the factory calibration card. The lowest setting on the FAT scale is 10 inch-pounds. I’m needing 8 for my work with G3 bindings. I was able to attain this by loosening the adjustment a few turns and verifying with my force gauge. Calibration could be checked by fixing the tool sideways in a vise, attaching visegrip pliers as in photo above, hanging a weight from the pliers at a given distance, then doing the math. This link explains the concept.

Conclusions:

FAT Wrench can be used without checking calibration if you jibe the settings with what you feel is correct. It works well for light torque such as the 8 inch-pounds required by G3. To do this I move the adjustment a bit below 10, then torque a screw that’s already been installed by feel. The tool will either click or turn the screw a bit more. If close, I just leave your setting as is. If it tends to not click and begins to overly tighten the screw, I back off the settings a turn or two. Once the adjustment is figured out, it can be marked on the scale with a Sharpie. In the case of ski binding mount screws set to about 45 inch-pounds and test on a couple of screws that are hand tightened. More torque might be required for metal top skis, and less for foam core with thin reinforcement plates. Overall, I’m enjoying this tool and doing well with my Rolex modifications.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.