Discerning spirit murmurs from the astral static is tough, but someone has to do it. With fingertips pressed to my forehead, I fold to the lotus and listen for the voice of Fritscheese. This ancient entity is something like perfectly crafted Swiss cheese only it can be re-frozen numerous times without any loss of flavor. Secret knowledge is revealed.

Turns out Tecton ski stoppers can be configured without the brake arms to make for a “brakeless” rig, and with a bit of care they’re not that tough to install during the mounting process (or when you decide to return from brakeless to brakes). Note this is not a review of the brakes, which have worked fine for us. This is a how-to on how to remove and install.

Fritschi Tecton on demo board with brake installed. I used my display prototypes for this so I wouldn’t risk messing up our binding test pair. Binding shown here in touring mode, for the brake removal and install set the binding as if it’s ready and “cocked” for heel step-in.

First step, whether binding is on ski or off, back off your vertical (upward) release tension so it’s easy to manipulate the binding cocking lever. As with any “alpine like” binding heel, in my opinion this is best done with the binding “closed” as if it has a boot in it, as shown here.

After loosening your forward (upward, vertical) release tension, cock the binding as if it is ready for downhill mode boot heel entry. This opens up the view on the side of the binding, so you can see the small plastic tabs that integrate with the brake.

Part one, we’ll remove the brake. First step is move the heel unit rearward using the boot length adjustment screw (rotate counter clockwise), until the binding disengages from the mount plate, then slide the unit backwards off the mount plate.

(Important: All Tecton brake removal and installation should be done with binding heel “cocked” as if ready for downhill skiing step-in at the heel.)

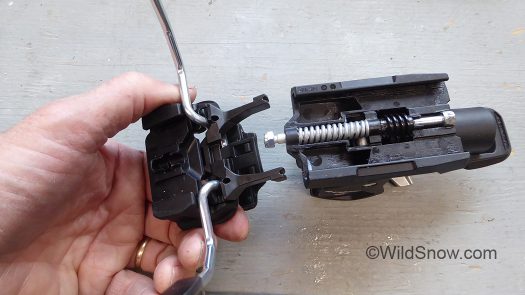

Examine underside, see that nut nested in its own pocket? Press the brake unit so that the nut disengages-lifts from the pocket, then firmly pull the entire brake unit off the heel unit. Removal is much easier than installation.

When the brake comes off it looks like this.

Next step is easy as well, again using firm pressure separate the brake pad unit (right) from the heel pad (left).

Sans brake arms, re-attach the heel pad to the heel unit, this step is intuitive.

Keeping the parts together, slide the heel unit onto the mounting plate, from the rear. Press the unit firmly forward while clockwise rotating the boot length adjustment screw, you should feel the screw immediately engage. If not, wriggle and otherwise persuade the heel unit forward, again rotating the adjustment screw. In some cases it may be necessary to “persuade” the heel unit forward with _light_ taps from a rubber mallet. Note that the mount plate and adjustment gear are plastic, damage is possible if you force things, so take your time and use minimal “persuasion.”

All done, adjust for boot length and carpe skium your brakeless Tecton.

Part 2, Install Tecton Brake:

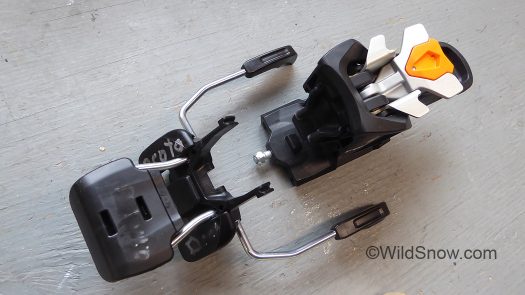

The challenge before you, three pieces (four if you count the mount plate on the ski).

First step, work with the parts flipped so you’re looking at the underside. Insert the brake arm holder into the heel pad. My first try with this was frustrating. The mating shapes are fairly obvious but the pieces wouldn’t go together. Trick is to tilt the brake arm holder as you press it in, per photo below.

Tilt the brake arm holder and it’ll slip into the heel pad. When you get the angle right almost no effort is required.

Next, the assembled brake needs to find its comfortable position, attached to the heel unit. You’ll again work with the parts flipped upside down, or from the side.

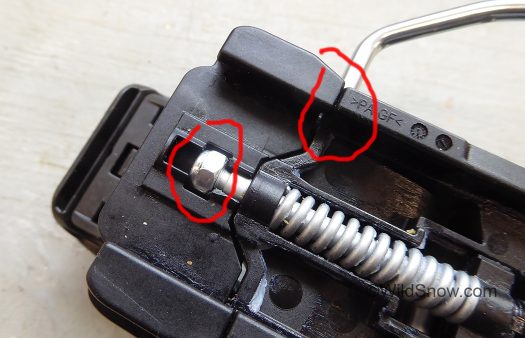

Slip the brake unit onto the binding heel unit, so the two plastic prongs made with the plastic tabs.

Another view of how parts need to integrate.

The other part of the process is to wriggle and otherwise convince the nut (circled in red) to nest in its slot. When you get all this right, the gap (red circle to right) will close up and everything will appear ready.

The completed heel unit should easily slide onto the binding mount plate, from the side it’ll look like this. As mentioned above, sometimes it’ll require some “English” to get the length adjustment worm gear engaging with the mount plate on the ski. Wriggle, press firmly forward, gently tap with rubber mallet if necessary.

And don’t forget, pressing ten fingers to your forehead will get you in touch with Fritscheese, though a rubber mallet can help as well.

Related links:

Our Tecton use review.

Tecton and Vipec Evo first looksee

Fritschi Tecton FAQ

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.