Our test rig uses a rope windlass to pull the binding open precisely 2.5 millimeters, measured with a feeler gauge.

[download spreadsheet PDF, know it’s a work in progress]

About the chart: All units are Newtons. When available, two different toe units were measured: “Toe 1” and “Toe 2.” We feel it’s desirable for toe units to show similar results, the “St. Deviation” column shows the mathematically derived standard deviation for the test numbers. We feel a lower deviation is better, but be aware that a Newton is a fraction of a pound, so deviations of only several Newtons are probably well within the accuracy limits of our testing methods, as well as being inconsequential to binding performance, and perhaps best ignored. Also, when we test two different toes the deviation will usually be higher, so don’t compare that deviation to bindings having only one toe tested.

This project measures the resistance of a given tech binding’s toe wings to opening, or put differently, how “tightly” the binding toe grabs your boot with what you could call its toe closure “strength,” or “force.”

It is tempting to call this the “spring strength” in lay terms, but that’s the wrong terminology so I’ll attempt to refrain. To get more specific, what is often called spring “strength” or “stiffness” is technically called “spring rate.” What I’m measuring is the force, in newtons, it takes to overcome the spring rate and open the binding. The spring rate can be calculated using the travel distance of 2.5 mm and the force. In this case, since we used the same amount of travel for all tests, mathematically deriving a spring rate is unnecessary.

Before we go farther, note that while in many (if not most) cases stronger toe springs may be desirable, softer springs are necessary for bindings with lower release-value (RV) ranges. Consequently, if you’re a skier who needs a binding that adjusts well below the proverbial “11” don’t get caught up in the “higher number ya better” game. On the other hand, one of the coolest thing about stiffer toe springs is you can often tour them without locking your binding toe — especially if you’re a smaller skier. If you like the idea of doing that, but due to your stature you need a binding that’ll set at around RV 5 or so, you’ll need a binding that is not at the top of the chart, but still reasonably stiff. As for me, I generally get good results with my release values at around 7.5. Nearly all the bindings on the chart get me there, with the possible exception of the Plum. There’s more about this here, with the caveat my release testing might stand for better engineering.

The variations of binding opening resistance visible in my test results come from a combination factors, everything from the geometry of the binding wings to yes, the spring rate. For example, virtually all tech binding toe springs have 3 “active coils,” but the wire diameter, length, overall spring diameter (and even the number of springs) changes between brands and models. In the case of our binding with the most opening resistance (Plum), the springs are clearly longer than others, thus allowing room for thicker wire.

How we test

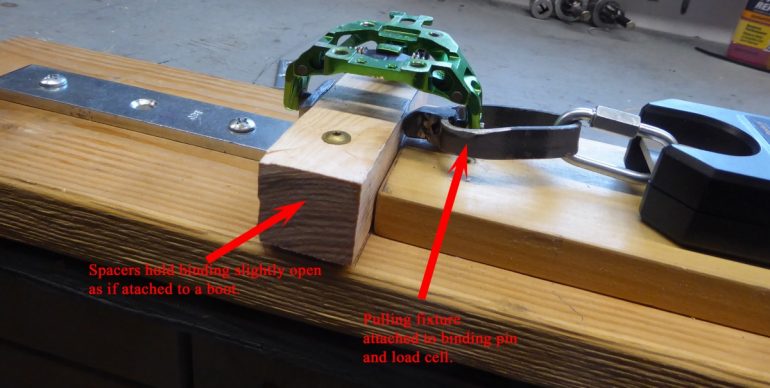

The test begins with the toe unit closed. A spacer holds the pins and wings in the same position-width as if clamped to a boot. The toe is then slowly and smoothly pulled open 2.5 millimetres, to the point just before it would pop completely open “over center” (as if you were opening the binding to step out).

Said another way: We test the binding jaw clamping force by pulling it open to the point just before it pops completely open.

We apply force and control the 2.5 mm “pull distance” with a windlass attached to the load cell with Dyneema cord. The pull distance is measured with a feeler gauge. We experimented with pulling the binding apart slightly farther than 2.5 mm, with minuscule to no change in required force. Thus showing our method works. In our prior test methods we pulled the binding completely open. Doing so caused fluctuations in measurement due to the violent nature of the binding “over center” opening process. Upon more experimentation, we found that simply pulling to “just before it opens,” with a slow and consistent use of the windlass and feeler gauge, made for repeatable results.

Enjoy our data but please don’t publish it, as it’s subject to revision as we refine our test methods and instrumentation. If you’ve got a spreadsheet formula you’d like us to try plugging in, please feel free to share.

Newcomers to WildSnow might wonder why the heck we’re going to the trouble to measure this? Two reasons. Most importantly, we have a theory that a certain kind of accidental binding release (pre-release!) can occur due to the tech binding toe wings opening while downhill skiing due to vibration and turning force. Also, in our opinion you can enhance your safety in avalanche terrain by ski touring uphill with bindings that don’t require locking the toe unless you’re doing stressful maneuvers such as steep kickturns. In our field testing, the bindings that rate highest for toe-jaw opening force can in many situations indeed be toured without the toe locked. And again, we theorize they are less prone to pre-release. All that said, see above for discussion of reasons why you might not want the stiffest binding out there.

For more, see our post listing 10 Tips to Prevent Pre Release, also see this post with a video explaining the issue.

Notes

While there are now many “hybrid” tech bindings, and some of those do not use the original tech pin toe, we’re assuming the “classic” tech binding toe design will stay viable for a few more years (heck, it’s been what, 30 years now?), so we’ve continued to refine our testing methods and machinery. The year 2020 rig shown here is our third iteration.About what we tested: Some of the bindings may be redesigned, under the same name. We dislike the confusion caused by that, but it’s apparently a reality of marketing. Check the dates we include with each binding. For example, the Marker Kingpin for 2020 is a much different binding than earlier versions.

Real-world use shows that most high quality tech bindings have adequate toe retention (with regards to accidental release due to toe wings/springs opening). But our testing reveals that larger aggressive skiers may want to pick the higher DIN version bindings simply because the toe spring strength is indeed higher, thus preventing pre-release due to the toe wings opening too easily.

The surprise here here was how much force it takes to pull the Plum binding. I’m pretty sure this is a good thing, but with more than twice the closure pressure as most other tech bindings, one wonders about possible wear — and don’t get your finger in there when a Plum chomps down on your boot fittings! You could end up visiting the hand surgeon.

We make an effort to test two different toe units per binding, in case of any marked discrepancy. Most are quite similar, while a few show differences that could be concerning. I measured each binding several times, and charted the two results I felt were the most consistent and from my smoothest most careful pulls.

Most importantly regarding variations of spring rate in the same model binding, what that should tell you is, yes, if you want to run your bindings as “safety release” bindings, you need to test the release on a shop machine as variations in the toe opening resistance (as well as variations in the binding release machinery) will cause variation in the actual “DIN” settings. This is a known issue — addressed by the DIN/ISO certification standards allowing rather extreme variations in release values compared to the numbers printed on the bindings.

Generation 1 tester in action, cable at top is a limiter strap to fine tune how far we pull apart each binding. Instrument is a hand strength dynamometer, hooked up as a 2/1 pulley system. While the values measured with this rig were a bit different than results from load cell (especially after we eliminated the friction of a pully), the relationships between the bindings remained the same.

DISCLAIMER: This project and the results are not intended to nor do they show any one binding to be superior to another. As covered above, there are both pros and cons to various levels of binding toe clamping force. Our data is subject to revision as we improve our test methods. Apologies to engineers out there for our bastardization of terms such as “force” and “strength.” We do study up on this stuff but we write in lay terminology using terms of art. For specifics about the physics of “force,” check out http://www.physicsclassroom.com/class/newtlaws/Lesson-2/The-Meaning-of-Force

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.