This test has been reworked and updated, see

https://wildsnow.com/18803/comparo-toe-jaw-closure-strength-marker-g3-dynafit/

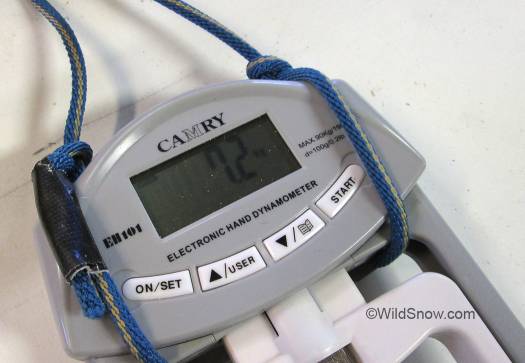

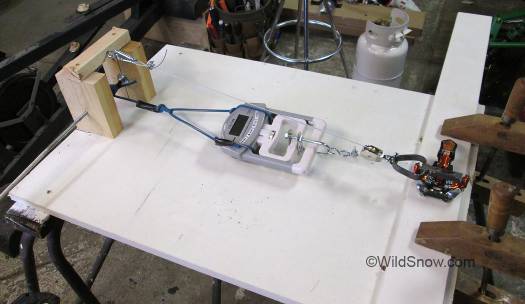

With a nod to Rick Howell (or should I duck?), I lashed up this tech binding pull-tester using a hand strength dynamometer for instrumentation. Ghetto? Idea is to compare toe wing opening pressure and spring “stiffness” (spring rate) between different brands/models. The results appear repeatable (though they vary more than I’d like to see), so here is a report. I did three samples for each test and averaged. For example, one test resulted in readings of 6.8, 6.6, 6.7, averaged to 6.7 kg.

First, to test-compare toe wing pressure and spring rate I rigged a nice setup that simply pulls the backcountry skiing binding wings open to the side. Clever me, I thought, until it became apparent that my nifty little fixture didn’t work for Dynafit bindings with power towers*.

So I went back to using a boot sole with a chamfered out tech fitting that exited smoothly from all tested bindings in a simulated side release.

(Without chamfering, the boot fitting caught on some of the binding toe pins and spiked the reading in a way that didn’t allow evaluation of spring tension. This “catching” problem is an ongoing concern with tech bindings in general, but not something this test is designed to accommodate). UPDATE: Solution for this was to build another system that eliminated the boot. See this post.

I had concerns about wear of the tech fitting changing my results. Turned out this was not a problem as I did so few samples. A few repeated tests verified this. In a test with more bindings care would need to be taken, as fitting wear would indeed mess up the results.

Original plan was to develop a chart with actual numbers, but the results varied a bit between individual bindings of the same model, around 15% in one case. Thus, without increased accuracy and a larger sample size for averaging I felt it irresponsible to try and do an exact listing of numbers and subsequent comparison.

Suffice it to say that the weakest springs we tested were in a quite old pair of tech bindings, measuring 6.1 kg with our method. Marker Kingpin 13 and Dynafit Speed Radical were also represented and did ok. I don’t mind naming names for the strongest, since even while doing hand checks you can feel how stiff the G3 ION springs are in comparison to other bindings. ION measured 7.7 kg, a full 25% stronger than our least stiff tech binding toe!

I know from my factory visit to G3 some years ago that they put a lot of design work into having beefy toe-spring tension. What is more, if you’re at all technical minded you can observe with the ION how “deep” the toe wing hinge (under the boot toe) folds down. My theory: In reverse, the toe wing hinge has a longer distance to travel before it goes “over center” and freely releases your boot.

The idea behind having strong springs in the tech binding toe is twofold. First, the added stiffness could make the binding more resistant to accidental release caused by the toe wings opening due to vibration or side force at the toe. Second, the stronger the springs the easier you can tour with the toe unlocked. Experience bears this out, as our strongest measured binding (ION) is the only one of our samples we can consistently tour with unlocked, in a practical sense.

Summary of my results so far:

Older tech binding, 6.1 kg (This binding was clearly weaker than the others, springs wear out, something to consider when using 20 year old bindings.)

Modern, “freeride” 6.3 kg

Modern, “freeride” 6.7 kg

Modern, “touring” 6.8 kg (Interesting the touring and one of the freeride bindings measured virtually the same, freeride must have stiffer springs in the heel, or at least I’d hope so.)

G3 ION 7.7 kg (strongest springs, 25% stiffer than weakest.)

*Note: In my opinion Dynafit Power Towers can help prevent pre-release due to tech toe opening to the side, but only if the boot toe shape causes the boot plastic to be quite close to the towers. You can test this on the bench.

Where this rig will come in handy is in testing manufacturer claims of stronger toe springs in various models (e.g., Kingpin 10 & 13). I’ll keep it activated and use as more binding samples come in. Oh, and since you’re going to ask, the way this is set up has no functionality to compare release tension of classic tech toes vs bindings such as Fritschi Diamir Vipec and Trab TR1. The geometry is too different for comparison.

Another view of the rig. Drill turns a simple windlass that pulls the test. I found that with a light touch on the drill I could pull at a gentle constant pressure that gave consistent readings. The drill is off the side of the table so it can be turned by hand for experiments needing tiny amounts of movement.

A note about tech binding springs:

Beyond and possibly more important than “safety” release, ski binding retention is the gorilla in the room. It doesn’t matter how good your bindings provide safety release, if you fly out of your grabbers unexpectedly. The springs in a classic tech binding toe are in a sense “decoupled” from the lateral release, meaning that as you adjust lateral release (usually by twisting a screw in the heel unit), the tension (technically, the “spring rate”) of the toe springs stays the same. What this means in a practical sense is that the larger aggressive skier gets the same toe springs as the 12-year-old. The youngster will have no problems with pre-release.

In my opinion classic tech binding toes can open accidentally while you’re skiing and cause pre-release. Some bindings perhaps more prone than others. The larger and/or more aggressive the skier, the more likely this is. The problem as I see it is that steel springs as used in tech bindings would ideally be a shock and energy absorber, but, instead they have an “undesirable recoil effect.”

According to the Enidine website

“…springs [in the case of shock absorption] have an undesirable recoil effect. Most of the energy absorbed by these at impact is actually stored. This stored energy is returned to the load, producing rebound and the potential for damage…”

In other words, if the perfect additional force is applied to a tech binding while it’s in the process of rebounding due to vibration or ski chatter, the binding toe could open more easily than you would expect. In my opinion this applies to all tech binding that use toe springs and wings with an over center pivot configuration (the “classic” tech binding toe design).

While an incredibly sophisticated “tech” binding could perhaps be built that damps shock instead of having springs that simply “rebound,” I don’t see that on the horizon (bear in mind that “rebound” is what causes the return-to-center action of most bindings, so it’s not all evil). Instead, the simple solution seems to be having fairly strong springs in the toe unit, with perhaps a slight tweak to the geometry of the toe wings. Again, as far as I can tell ION is the best example of this. Other current products such as Marker Kingpin and Dynafit Radical also have strong springs that appear to perform well.

Unfortunately, the only real test for how well a tech binding does with retention is to ski it at “normal” release values, unlocked, and see if you experience flight sans ski. In my experience, very few skiers set their tech bindings at chart value. Even if they do, it is rare to have the binding tested on a machine to be sure it’s actually delivering values as assumed. Thus, stories about how “great these bindings are, I never come out” should be suspect until the DIN/ISO 13992 norm is revised for better testing of shock absorption and retention, bindings are tested by an independent lab to match or exceed the new standard, and skiers have their bindings tested individually for release values and use them consistently at “normal” settings, unlocked.

Our pull tester rigged to simply check binding toe opening force by pulling a binding wing. I’m not 100% convinced this works correctly. The dynamometer does measure a peak load and the 2×1 pulley system doesn’t overload the instrument. I’ll add more info here as I refine the process.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.