It all began with Mountain Equipment (ME), the UK gear maker who recently began importing their excellent softgoods line to the States. ME’s “Down Codex” program is designed to track bird plumage insulation from the animal all the way to your sleeping bag or other “end use,” so you know what you’re buying (quality control) and how the animals were treated in getting you the goods (animal welfare).

Interestingly, one of the UK guys at Mountain Equipment told me that his impression is that consumers in Western Europe are much more concerned about the animal welfare part of this than those of us in North America. I don’t know if that’s really true, but have to say his impression got my attention. How about you WildSnowers? Any of you concerned with tracking how that down in your jacket is obtained? One interesting factoid regarding all this is that most down is actually a byproduct of the food industry (about 96% of the value of a goose is the meat). Because of that, how the birds are treated for food production is where the issues may be; force feeding and that sort of thing.

Having thus recently become interested in feathers, I got in a conversation with ME and they suggested a visit to the International Down and Feathers Lab (IDFL) to check out how down is tested and standardized — the “quality” part of the Codex equation. IDFL’s world headquarters are in Salt Lake City (with facilities around the world), so during Outdoor Retailer I spent a few hours getting the tour. Fascinating. Check it all out below (click images to enlarge).

Due to legal labeling requirements, IDFL receives thousands of samples for evaluation. Testing the super fill down used by the outdoor industry is just a small part of what they do -- but to us an important part!

Smaller down samples lined up for content evaluation and more. Larger samples are tested for fill power. This is where if you try to slip chicken feathers into a 'down' filled product, you get busted.

In this lab they measure how much dirt is in the down, and check that it's been sterilized by doing an 'oxygen' test for organic matter. One constant question about down is how do you wash it? I asked these total experts. They told me 'you can wash down a hundred times (if you do it correctly) with no damage.' What does 'correctly' mean? Just use regular laundry detergent, and rinse well while taking extra care not to damage the garment or sleeping bag with the weight of the wet down. I also asked about the special 'down washes' available. The IDFL guys said they're not much different than regular laundry detergent, only they rinse out easier due to some additives.

Small pillows are stitched up to test the down (or synthetic fill) proof-ness of fabrics. The pillows are placed in a rubbing machine, tortured in a 'punch test' machine, and pummeled in a contraption that resembles a ball mill in an ore processing facility. The IDFL guys told me that it's quite a challenge to make super-lightweight fabric that's truly down proof, and this kind of testing is key to research and development. They said the fabric tests are a huge part of what they do, and an immense amount of work since multiple tests are required.

Pillow in the rubbing machine to test how down proof the fabric is. Any fill material that exits is counted and evaluated.

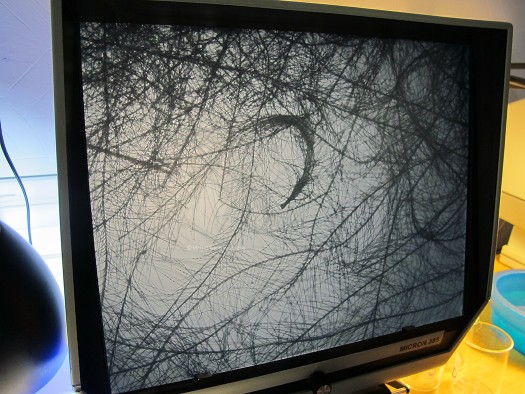

Content analysis is also a big part of IDFL's testing and evaluation. This is all done by amazingly talented 'counters' who tweeze and sort the different fill components (feathers, down clumps, trash, etc.). Since down is a 'non homogeneous natural product,' this sort of evaluation is super important to perform on every batch, unlike synthetic fills that can be manufactured in nearly identical mass quantity. (Though synthetic fills also must be tested to one degree or another).

Fill power. The test everyone talks about turns out to be just one part of the total equation -- but nonetheless super important. This is the test that says to us consumers 'here is the real stuff!' First step is 'conditioning' the down. The moisture content has to be adjusted and the down is fluffed to a consistent degree. This step is done by steaming then drying, or tumble drying. Consistency is key. While conditioning methods vary, the same fill power test is used around the world. Known at the 'Lorch' test, it simply involves filling a cylinder with down, placing a weight on top, and seeing how much the down compresses.

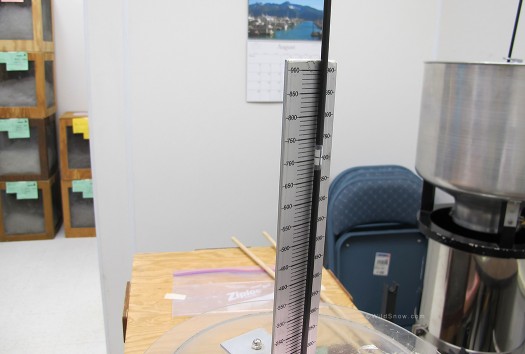

Lorch cylinder with top on and the weight compressing the standard 30 grams of down, a simple rod indexes on a ruler. This ruler is scaled for down or feathers with lesser fill power.

The good stuff scale for the Lorch test, yeah, it goes to 900. Kind of like an amp that goes to eleven since most 'premium high fill down' is around 800, and true 900 fill is said to be difficult to reliably separate from a down harvest, thus pricey and in some cases perhaps more of a PR and marketing story than reality.

Next, Part Two is an essay on down fill standards, or lack thereof in the outdoor industry.

As it were, we recommend a quality down puff jacket for backcountry skiing in all but the wettest climates. Get ready for winter and shop for it!

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.