Some folks think I’m nuts, but I have just as much fun visiting ski touring equipment factories as I do Europe’s historic cities, lakes and mountains (though the ultimate gasthaus might be superior to any of those). The Fritschi plant in Switzerland looks, well, Swiss. Clean and well lit, lots of space. Binding parts everywhere along with specialized assembly machines and jigs, much of the stuff made custom in their own machine shop.

The release checker in video above is important. They run every binding toe through it and record the results. Serial number is stored along with the numbers in a database. We watched several tests and the results were impressively consistent. Way closer than what I recall the DIN/ISO binding standard allows for variation.

Aha, a Vipec backcountry skiing toe in 'walk' mode, with small white plastic tab (circled) jammed in slot to block play in the binding.

Play that the 'lockout' blocks is caused by the release mechanism. Shown here, the 'carriage' that slides left and right, allowing the binding to open up and hopefully prevent things like ripping ligaments.

At this station in the plant, the Vipec toe carriage gets more assembly. Manufacturing of individual binding parts happens around Europe, final assembly is at Fritschi facility here in Switzerland.

Brakes for Diamir ski touring bindings, similar selection will be available for Vipec, only with Vipec you'll simply swap in the metal arms.

The 3-D printer. These things are so radical. Soon just about anything you buy will be printed at a local location? Even ski bindings?

Ah, lunch. One of the best potato soups I've ever had and the historic gasthaus wasn't too shabby. During these press trips we appreciate being hosted to authentic local cuisine, even if it seems a yawner to the locals.

Assembly of this backcountry skiing binding is mostly a hand process, automation of this is quite difficult.

Yeah, we published this before but did it again. The adjustable toe pin on Vipec is factory set to what Fritschi feels is the 'standard' pintech width dimension. And indeed, it IS adjustable because no real standard exists.

In our Switzerland hotel we watched watch wide-screen TV, it's tuned to the Fritschi binding safety release checking machinery. Seriously, anywhere in the country you can hit channel 142 and see the Fritschi release checker, real-time action. See video above for an example. Remember, channel 142 for binding checker action!

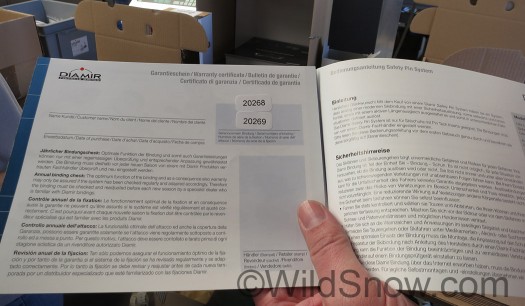

Each binding is packed with a user manual stamped with the binding serial number. This occurs after the safety release check, the data set of which is stored for later retrieval if for example someone does get hurt while using a binding.

Since the question keeps coming up, another photo of Vipec in walk mode showing how the small white plastic tab inserts into a slot and blocks some of the toe carriage movement. Again, know that this is NOT a release lockout, the binding can still easily safety release in tour mode.

In all, a fun visit that inspired a lot of confidence in what Fritschi is doing with tech ‘pintech’ backcountry skiing bindings.

WildSnow.com publisher emeritus and founder Lou (Louis Dawson) has a 50+ years career in climbing, backcountry skiing and ski mountaineering. He was the first person in history to ski down all 54 Colorado 14,000-foot peaks, has authored numerous books about about backcountry skiing, and has skied from the summit of Denali in Alaska, North America’s highest mountain.